Continuous Improvement lies at the core of LEAN philosophy, serving as the driving force behind its principles and practices. I worked at TMMC (Toyota Motor Manufacturing Canada) for 10 years, and no one takes Lean as seriously as they do at Toyota! Although we never referred to or called it lean. It was TPS or Toyota Production System. While there, I had the unbelievable privilege to attend Lean (TPS) management training in Japan in preparation for opening the first Lexus manufacturing facility outside of Japan.

This experience was unlike anything else I have ever had. I was taught by Lean Sensis, with a specific focus on 1/10th of a second kaizens. Yes, you read that correctly: 1/10th of a second improvements and kaizens to production lines!

All of us in the program would spend all day looking for ways to improve specific parts of the process only to have these Sensis’ tare up everything we proposed over and over again until we finally got it just right. While this may not be the most encouraging form of teaching, we did learn a lot!

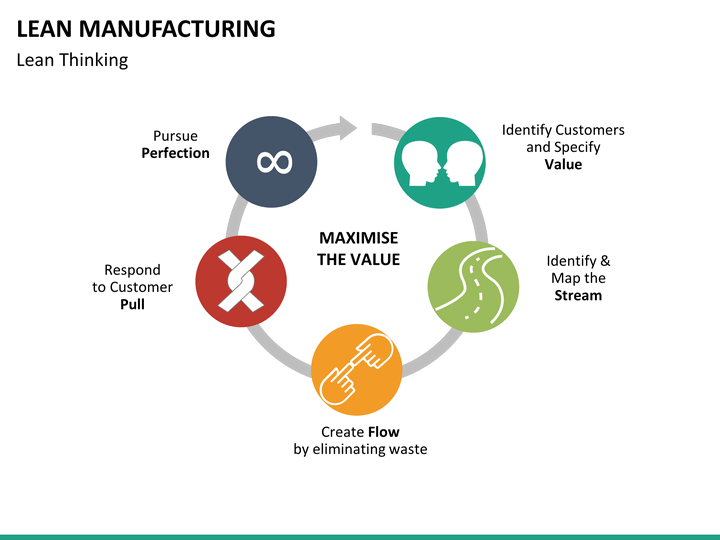

Today, Lean is so much a part of my leadership toolbox that I often find it disconcerting to see other leaders not taking advantage of these practices. While Lean may have originated as a manufacturing concept, it can be applied in any function or industry.

Understanding Continuous Improvement in LEAN

Continuous Improvement, often referred to as Kaizen in the context of LEAN, is a concept rooted in the idea that small, incremental changes can lead to significant enhancements over time. It’s not just a methodology; it’s a mindset that permeates every aspect of an organization. At its essence, continuous improvement involves:

1) Incremental Progress:

One key tenet of continuous improvement is the emphasis on incremental progress. Instead of waiting for major overhauls, LEAN encourages organizations to focus on making small, consistent improvements in processes, systems, and workflows. This approach not only minimizes the disruption that can come with large-scale changes but also allows for a more agile and adaptive organization.

Incremental progress is akin to the proverb, “A journey of a thousand miles begins with a single step.” Small changes are more manageable, less risky, and easier to implement, fostering a sense of achievement and momentum within the organization. It’s about cultivating a mindset where everyone is encouraged to identify areas for improvement and take actionable steps toward positive change.

2) Employee Involvement:

At the heart of continuous improvement is the active involvement of every team member, regardless of their role within the organization. LEAN philosophy recognizes that those closest to work often have the most valuable insights into its improvement. Therefore, fostering a culture where employees feel empowered to contribute their ideas and perspectives is crucial.

To achieve this, organizations need to create an environment that encourages open communication and collaboration. This involves recognizing and rewarding employees for their contributions to continuous improvement, whether through formal initiatives, team huddles, or regular team meetings dedicated to discussing improvement opportunities. When employees are engaged in the improvement process, it not only leads to better solutions but also cultivates a sense of ownership and commitment to the organization’s success.

3) Data-Driven Decision Making:

Another cornerstone of continuous improvement in LEAN is using data and feedback to inform improvement initiatives. This ensures that changes are based on evidence rather than assumptions. Data-driven decision-making involves collecting and analyzing relevant data to identify trends, problems, inefficiencies, and areas for enhancement.

Implementing key performance indicators (KPIs) and other metrics allows organizations to measure the impact of changes objectively. This data-centric approach enables teams to identify what is working well and needs improvement, leading to more informed and effective decision-making. It also provides a basis for setting realistic goals and measuring progress over time, contributing to the sustainability of continuous improvement efforts.

Ways To Implement LEAN

1) Waste Reduction:

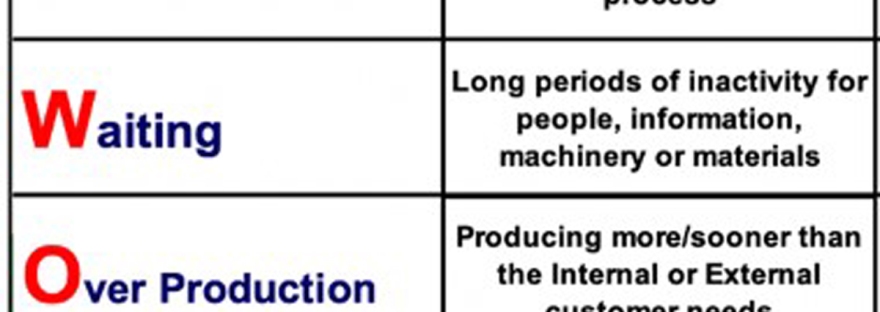

In the LEAN philosophy, waste reduction is a cornerstone, targeting the elimination of waste in all its forms – be it time, resources, or effort. Continuous improvement plays a pivotal role in achieving this objective by systematically identifying and eliminating non-value-added activities. The process involves a meticulous analysis of workflows to identify activities that do not contribute to the end product or customer satisfaction. TIM WOODS is a great way to eliminate the seven areas of waste. For more info on how this works, please visit our TIM WOODS article.

Continuous improvement encourages teams to question the status quo, seeking ways to optimize processes and minimize unnecessary steps. This not only leads to more efficient resource utilization but also contributes to operational efficiency. Identifying and eliminating waste can take various forms, such as reducing excess inventory, minimizing waiting time, or optimizing transportation routes.

A key aspect of waste reduction through continuous improvement is the engagement of all team members. Employees are encouraged to be vigilant observers of their workflows, actively participating in the identification and elimination of waste. This collaborative approach fosters a sense of ownership and responsibility, creating a culture where continuous improvement becomes ingrained in the organizational DNA.

By systematically addressing waste, organizations not only enhance their operational efficiency but also create a leaner, more agile structure that is better positioned to respond to changing market conditions.

2) Enhanced Productivity:

Continuous improvement, as facilitated by the LEAN philosophy, is a catalyst for enhanced productivity within organizations. This is achieved by consistently refining processes, streamlining workflows, and identifying and mitigating bottlenecks that impede efficient operations.

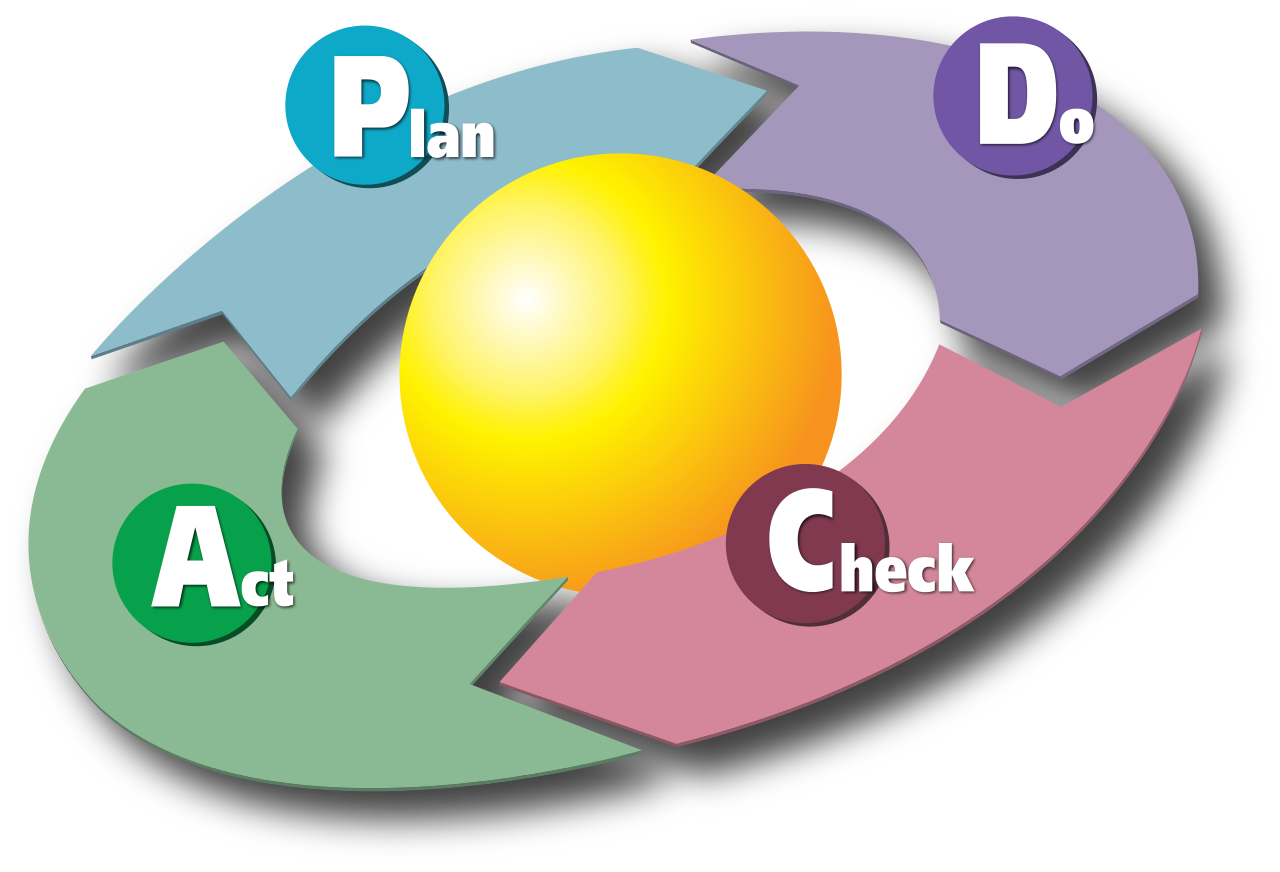

As teams embrace the mindset of continuous improvement, they engage in a perpetual cycle of evaluation and enhancement. The best practice to adopt is PDCA, Plan, Do, Check, Adjust. This ongoing process allows for the identification of inefficiencies and the implementation of changes to improve productivity. It’s about not settling for the status quo but rather seeking opportunities to optimize the use of resources and time.

Refining processes through continuous improvement eliminates redundant steps, adopts more efficient tools and technologies, and establishes standardized procedures. Collectively, these improvements contribute to a more streamlined workflow, reducing the time and effort required to complete tasks.

Quicker delivery of products or services to customers is a direct outcome of enhanced productivity. The overall production cycle shortens as teams become more adept at their tasks and processes become more efficient. This not only meets customer expectations but also positions the organization as more competitive in the market.

Moreover, enhanced productivity has cascading effects on employee morale. When teams witness the positive impact of their continuous improvement efforts on overall efficiency, it fosters a sense of accomplishment and pride. This positive feedback loop further motivates teams to actively engage in the pursuit of continuous improvement, creating a culture that values and prioritizes productivity.

3) Customer Satisfaction:

Customer expectations are dynamic and influenced by factors such as market trends, technological advancements, and competitors’ offerings. A commitment to continuous improvement requires organizations to stay attuned to these shifts, continually reassessing and recalibrating their processes to align with evolving customer expectations.

By actively seeking and incorporating customer feedback, organizations can gain valuable insights into areas that require enhancement. Continuous improvement methodologies, such as Kaizen in LEAN, emphasize the importance of involving customers in the improvement process. This engagement not only helps in identifying pain points but also allows organizations to tailor their offerings to better meet customer needs.

Proactive Problem Solving:

Continuous improvement encourages a proactive approach to problem-solving. Rather than reacting to customer complaints or issues after they arise, organizations adopting LEAN principles focus on anticipating potential problems and addressing them pre-emptively. This proactive stance not only mitigates negative experiences but also demonstrates a commitment to delivering consistent quality.

Teams engaged in continuous improvement regularly analyze customer feedback, identify recurring issues, and implement corrective actions. This proactive problem-solving approach contributes to a smoother customer experience, reducing the likelihood of disruptions or dissatisfaction.

Building Customer Loyalty:

Satisfied customers are more likely to become loyal brand advocates. Continuous improvement, by consistently delivering enhanced value, contributes significantly to building customer loyalty. When customers perceive that an organization is actively working to improve its offerings based on their feedback, it fosters a sense of partnership and mutual growth.

Practical Tips for Fostering a Culture of Continuous Improvement

- Leadership Support and Commitment:

- Begin with strong leadership support, emphasizing the importance of continuous improvement.

- Leaders should actively participate in improvement initiatives and communicate their value throughout the organization.

- Organize kaizen events and attend kick-offs, daily updates, and final-day report-outs to encourage, remove barriers, provide resources, and celebrate success.

- Establish Clear Goals:

- Define clear and achievable improvement goals aligned with organizational objectives.

- Break down larger goals into smaller, manageable tasks to facilitate incremental progress.

- Encourage Open Communication:

- Create a culture where employees feel psychologically safe and comfortable sharing their ideas and concerns and learning from mistakes.

- Implement regular feedback mechanisms and channels for obtaining employee suggestions and improvement ideas, ensuring everyone’s voice is heard.

- Provide Training and Resources:

- Equip employees with the necessary skills and knowledge to identify improvement opportunities.

- Invest in training programs that foster a mindset of continuous learning and development.

- Celebrate Successes:

- Recognize and celebrate both small and large successes resulting from continuous improvement efforts.

- This not only boosts morale but also reinforces the importance of the ongoing continuous improvement process.

- Utilize Lean Tools and Techniques:

- Implement LEAN tools such as Value Stream Mapping, 5 Whys, and Gemba Walks to identify areas for improvement.

- Regularly assess processes using these tools to pinpoint inefficiencies and opportunities for enhancement.

- Foster a Learning Environment:

- Encourage a learning culture where mistakes are viewed as opportunities to learn and improve.

- Share stories of successful improvements to inspire others and reinforce the positive impact of continuous improvement.

Continuous Improvement is not just a buzzword in LEAN philosophy; it is the heartbeat that keeps organizations alive and thriving. By embracing the concept of ongoing refinement, businesses can stay agile, reduce waste, and ultimately deliver greater value to their employees and customers. Cultivating a culture of continuous improvement requires commitment, leadership, and a genuine belief in the transformative power of small, incremental changes. As organizations navigate the complexities of the modern business landscape, they must recognize that the path to excellence is a journey marked by continuous improvement.

If you would like to take a course with me to learn more about Lean, sign up for my next Lean 4 Leaders Bootcamp!