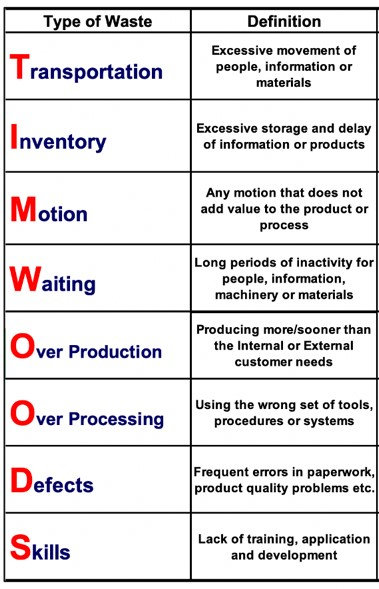

Teams encounter unexpected challenges, projects veer off course, and crises arise when least expected. Many leaders find themselves caught in a perpetual cycle of “firefighting,” where they spend their days extinguishing problems within their teams, only to find themselves exhausted and unproductive by day’s end. This constant state of reaction leaves little room for proactive, strategic leadership—working on the business rather than just for it. Calling ourselves “firefighters” actually discredits real firefighters, as they have extensive training and the tools they need to do their job, while many leaders do not.

The “firefighting” mentality stems from a reactive mindset—a tendency to focus solely on addressing immediate issues rather than thinking strategically about long-term goals and objectives. While putting out fires is an essential skill for any leader, it should not dominate their entire approach to leadership. Leaders must learn to balance reactive problem-solving with proactive, strategic thinking.

Through many of my mentorship conversations with young leaders, I see they are in a chronic state of chaos. They spend most of their days running from one crisis to the next. Whether we meet once a week or every few months, their answer is always the same, “I’m just too busy, and I never have enough time to get my projects done.” This leaves me with one question: if chaos is the standard…. why do you not have standardized work for crisis management?

Sound crazy?

Consider professions in perpetual crises, like paramedics, firefighters, or military personnel. Anyone working in these industries is given extensive training and the proper tools and support to do their job. In addition, they have even been trained to make do without the right tools or when separated from their team. They improvise.

Why do we not adopt similar principles as leaders?

Call It What It Is!

I have said this many times, but I will repeat it: If you are in a crisis, call it a crisis! Identifying what state we are active in removes ambiguity about what we are experiencing and allows us to access the tools and skills we need to lead through these challenges.

Think of a natural disaster or a political movement when a city or province announces a state of emergency. By making this statement, those in trouble will have more access to the necessary resources to deal with the crisis immediately. We should be doing the same as leaders. So call a crisis a Crisis!

Now that we have established that we are in a crisis, what next?

My Top Tip In Crisis Management

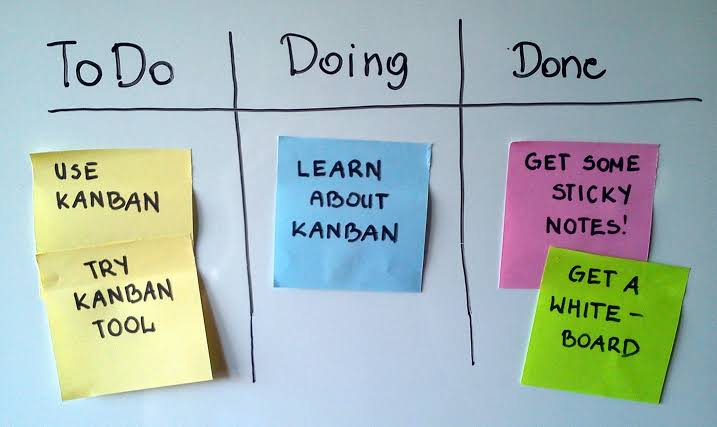

My top tip is to schedule time to deal with the crisis. I used to call it the “Daily Critical Meeting.” Like a morning huddle, those necessary to deal with the crisis will gather at the start and end of the day. Twice a day is usually frequent enough for most issues, but if the situation changes rapidly, consider having three or even four standard times per day for critical meetings. This time is scheduled into everyone’s calendars and stays constant until the crisis has been dealt with. Doing so dramatically reduces the need to cancel other meetings at the last minute, reduces the risk of missing other tasks or responsibilities, and generally messes up everyone’s schedule for the day. These meetings are meant to be short and used to delegate tasks and give updates on the situation.

Only relevant team members should be included in these meetings. This means that if the whole team is scheduled for the crisis meeting, but the crisis only affects the marketing team, then only marketing team members should be present. This gives all other team members free time to work on different projects and streamline meetings as efficiently as possible. Be sure to let your whole team know who is required at the meeting and who isn’t. Respect their time and abilities, and don’t forget to let everyone know what is happening, with ample time to prepare. Otherwise, you will create an additional crisis over your preexisting crisis.

Use the morning meeting to delegate tasks and the afternoon meeting to regroup, assess your progress and make a tactical plan for the morning.

When You Are In The Trenches

You may be thinking, “But Glenn, this all sounds great, but there’s no way I can implement this stuff. It’s too hard!”

I understand. Change can be challenging, and often, when we are in crisis, the last thing we need is to add gasoline to a brush fire. However, the best thing leaders can do during a crisis is to create routines. This provides some much-needed stability. Maybe your team is busy troubleshooting, and no planned work is getting done, but you can rely on those two meetings daily as a foundation to cling to—a calm in the storm, sort of speak. It is a time when everyone knows they will have a chance to be heard and supported.

Ultimately, it comes down to the severity and scope of your crisis. When crises happen, allow them to be discussed and dealt with only during crisis meetings, not anywhere else. The reverse is also the same: don’t bring your crisis to your other meetings.

Depending on the crisis, this may be altered slightly based on time-sensitive information or action requirements. However, for the most part, the time between these crisis meetings should consist of your pre-planned work day.

This allows you to get other non-crisis work done while managing a crisis. In my experience, 90% of crises do not need your immediate action or reaction. They need rapid action, but typically, they can wait an hour or so until the planned crisis meeting time. It’s usually our internal adrenaline rush or subconscious need to feel important that drives the “drop what you’re doing mentality” more so than the actual urgency of the task. So, take a moment to stop and think critically. Can this wait until the next crisis meeting? Nine times out of ten, the answer is yes! So save yourself the headache and stop getting pulled off your work when you don’t have to.

Put On Your Oxygen Mask Before Assisting Others

Another key to dealing with the crisis is to allow time for you to do what you need to maintain at the top of your game. You can’t have it all, but what are your top three non-negotiables?

My top non-negotiables have always been:

- Time to talk to/see my family

- Respect for my team and my leadership

- Look after myself and my team

The first non-negotiable may seem strange. However, throughout my career, I travelled extensively and was away for extended periods or had to deal with extended, very busy periods. For example, when I was at Amazon, “Peak,” or the Christmas season, was a CRAZY busy time of year. It was definitely 24/7 and often felt like one perpetual crisis. In these situations, it’s too easy to get caught up in things and miss the opportunity to connect with your family. Particularly when different time zones come into play! I wish I could say I developed this proactively, but no, I had to learn it the hard way! That’s why non-negotiable #1 exists for me. No matter what, no matter where I am, I will take time every day to touch base with my wife and kids. Even if I only have 15 minutes for a phone call, I will make that call just to hear their voices and catch up with their day.

Non-negotiable #2 is important to me because, earlier in my career, I experienced some situations where, during a crisis, more senior-level leaders reacted to the situation by being abusive and overly demanding of me and my team members. I’m sure they thought they were doing the right thing and that it would “motivate” us to resolve the issue faster. As you might expect, however, it was a distraction and caused many other issues that did not help the situation. From then on, I ensured that I ran interference for my team from the above levels and did not allow anyone, regardless of their position, to treat my team poorly, even at the risk of my career. It may be hard to believe, but some intense interventions were required!

Lastly, you’ve got to look after yourself. Despite what you may think, you are not immortal. Sure, you may think you can get away with eating poorly, not exercising, and, most commonly, not getting enough sleep. However, these things catch up with you eventually. Unfortunately, when they do, it’s too late. Look after yourself; in so doing, you may even be looking after your team. It seems I’ve learned these non-negotiables the hard way. One particularly difficult new model launch at Toyota, I was working around the clock to demonstrate my support and commitment to the company and my team. Leading by example was my intention. With two shifts operating, I thought it was important that both shifts saw my dedication and presence, so I worked very long days, spanning both shifts. One evening around 10:00 PM, as we stood observing a problematic process, one of my team members said to me, “How long are you gonna keep this up? We can’t keep up with you. You’re killing the team!” It was a well-deserved and, frankly, overdue slap in the face.

Although I had the best intentions, I didn’t realize that other team members were putting in crazy hours, too, just because I was. They didn’t want to be perceived poorly in my eyes, which they wouldn’t have, but that was their thinking. I was devasted that I had burdened my team, which was working as hard as possible to resolve the issues. Not only was I killing myself and reducing my effectiveness by becoming worn out and exhausted, but I was doing the same to those who were working diligently on resolving the issues! Staying rested, energized, and clear-headed wins!

Recap

As a leader, unexpected challenges and crises are par for the course. Many leaders find themselves trapped in a cycle of “firefighting,” where they spend their days reacting to immediate issues, leaving little time for proactive, strategic leadership.

However, this reactive approach can be detrimental. Leaders must shift from firefighting to crisis management excellence, adopting structured protocols and prioritizing self-care. By acknowledging crises, scheduling dedicated crisis meetings, and maintaining non-negotiables for personal well-being, leaders can effectively navigate chaos and lead their teams to success.